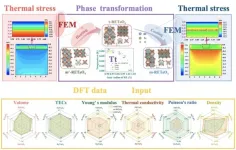

Thermal barrier coatings (TBCs) are widely used in gas turbine engines to obtain elevated working temperatures and improve engine efficiency. The phase transition of the ceramic layer is accompanied by a large volume difference, causing the concentration of thermal stress, eventually leading to TBCs to fall off and fail. Therefore, it is necessary to quantitatively evaluate the magnitude and distribution of thermal stress induced by phase transition in the ceramic layer.

A team of material scientists led by Prof. Xiaoyu Chong from Kunming University of Science and Technology in Kunming, China recently established a high-throughput multiscale evaluation method for thermal stress in TBCs that considers the phase transition of the top ceramic materials by coupling first-principles calculations with finite element simulations. The method quantitatively evaluates and visualizes thermal stress of the real TBCs structure under thermal cycling by multifield coupling, which can provide an important theoretical basis and guidance for the life prediction and reverse design of coating materials.

The team published their work in Journal of Advanced Ceramic on April 8, 2024.

“In this report, we develop a high-throughput multiscale evaluation method for thermal stress in multilayered systems, which considers the phase transition of the top ceramic materials by coupling first-principles calculations with finite element simulations. This approach can quantitatively evaluate and visualize the thermal stress in TBCs based on real structures, considering the actual service environment subjected to thermal cycling. The thermophysical properties input in finite element simulations are calculated by first-principles calculations, in which the multiscale method can consider the influence of phase transition and temperature and simultaneously reduce the cost and time of obtaining thermophysical properties by experiments.” said Xiaoyu Chong, a professor at the Faculty of Materials Science and Engineering at Kunming University of Science and Technology (China), and one young expert whose research interests focus on the field of high-throughput multiscale computing and machine learning.

It is challenging to directly observe the phase transformation process of ceramic coating. As one of the main reasons for coating failure, thermal stress is lack of quantitative testing and characterization methods, and the high temperature service environment also increases the difficulty of phase transformation thermal stress testing. “The finite element simulations coupled with multiple physical fields can visualize and quantitatively evaluate thermal stress of TBCs. However, the thermophysical properties required for finite element simulations are derived from experimental measurements, which ignores the effects of phase transition and temperature.” Mengdi Gan said, the first author of this paper and a Ph.D. student supervised by Prof. Xiaoyu Chong.

Here, we develop a high-throughput multiscale evaluation method for thermal stress in multilayered systems, which considers the phase transition of the top ceramic materials by coupling first-principles calculations with finite element simulations. This approach can quantitatively evaluate and visualize the thermal stress in TBCs based on real structures, considering the actual service environment subjected to thermal cycling. The thermophysical properties input in finite element simulations are calculated by first-principles calculations, in which the multiscale method can consider the influence of phase transition and temperature and simultaneously reduce the cost and time of obtaining thermophysical properties by experiments. In this work, rare earth tantalites (RETaO4) are introduced as ceramic layers, and the results demonstrate that thermal stress undergoes a rapid escalation near the phase transition temperature, particularly in the TBCs_GdTaO4 system. This discontinuity in thermal stress may originate from the large alterations in Young's modulus and thermal conductivity near the phase transition temperature. The TBCs_NdTaO4 and TBCs_SmTaO4 systems exhibit noteworthy temperature drop gradients and minimal thermal stress fluctuations, which are beneficial for extending the service lifetime of the TBCs. This approach facilitates the prediction of failure mechanisms and provides theoretical guidance for the reverse design of TBCs materials to obtain low thermal stress systems.

Other contributors include Mengdi Gan, Tianlong Lu, Wei Yu, Jing Feng from the Faculty of Materials Science and Engineering at Kunming University of Science and Technology in Kunming, China.

This work was supported by the Yunnan Major Scientific and Technological Projects (No. 202302AG050010), the Yunnan Fundamental Research Projects (Nos. 202101AW070011 and 202101BE070001-015), the National Natural Science Foundation of China (No. 52303295), the Project Funds of “Xingdian Talent Support Program”.

About the Authors

Dr. Xiaoyu Chong is a full professor in the Faculty of Materials Science and Engineering, Kunming University of Science and Technology, China. His research interests focus on the algorithm and software development of multi-scale integration such as first-principles calculations coupled with thermodynamics and machine learning. Until now, he has published more than 100 papers in Acta Mater and other journals, presided over 20 national/provincial scientific research projects, owns 32 invention patents. For more information, please pay attention to his research homepage https://clxy.kmust.edu.cn/info/1027/3725.htm.

About Journal of Advanced Ceramics

Journal of Advanced Ceramics (JAC) is an international journal that presents the state-of-the-art results of theoretical and experimental studies on the processing, structure, and properties of advanced ceramics and ceramic-based composites. JAC is Fully Open Access, monthly published by Tsinghua University Press on behalf of the State Key Laboratory of New Ceramics and Fine Processing (Tsinghua University) and the Advanced Ceramics Division of the Chinese Ceramic Society, and exclusively available via SciOpen. JAC has been indexed in SCIE (IF = 16.9, top 1/28, Q1), Scopus, and Ei Compendex.

About SciOpen

SciOpen is a professional open access resource for discovery of scientific and technical content published by the Tsinghua University Press and its publishing partners, providing the scholarly publishing community with innovative technology and market-leading capabilities. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, and identity management and expert advice to ensure each journal’s development by offering a range of options across all functions as Journal Layout, Production Services, Editorial Services, Marketing and Promotions, Online Functionality, etc. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END