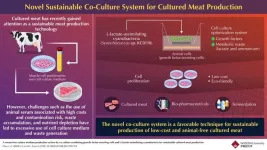

There is a pressing need for environmentally friendly meat production technologies to tackle the increasing global food demand. Cultured meat production is one such technology that is attracting a lot of attention as an alternative to conventional meat production. First developed in 2012, cultured meat is simply meat that is produced by growing or culturing muscle cells from animals in a laboratory.

Typically, cultured meat production requires serum (or the liquid part of the blood) from animals, which is essential for the growth of muscle cells in the culture medium since serum includes abundant proteins that promote muscle cell growth. The use of animal serum poses significant challenges due to multiple reasons such as high costs, risk of contamination, and ethical concerns. Hence, there is a need for culture methods that allow muscle cells to grow without the use of serum.

Now, a research team led by Professor Tatsuya Shimizu from Tokyo Women’s Medical University, along with Ph.D. student Shanga Chu and Professor Toru Asahi from Waseda University, Professor Yuji Haraguchi from Tokyo Women's Medical University, and Professor Tomohisa Hasunuma from Kobe University, have developed a new system for culturing muscle cells without serum by using photosynthetic microorganisms. Their findings were published in Scientific Reports on August 23, 2024.

Normally, animal serum provides proteins called growth factors that are essential for the growth of muscle cells. However, rat liver cells are also known to secrete these growth factors. The researchers discovered that the medium remaining after culturing these liver cells (or the supernatant) contains growth factors, and can support muscle cell growth without the use of serum. “Although more growth factor-secreting cells and longer cultivation produce larger amount of growth factors, the downside is that the cells also produce waste products like lactate and ammonia into the medium at the same time, which eventually hinders muscle cell growth,” explains Shimizu.

Hence, waste removal is crucial to improve the performance of this culture supernatant as an alternative to animal serum. To resolve this, the researchers had developed L-lactate assimilating cyanobacteria (photosynthetic microorganisms) with lactate to pyruvate converting genes, which were capable of taking in harmful waste metabolites, such as lactate and ammonia and converting them into nutrients for animal cells (rat liver cells and muscle cells), such as pyruvate and amino acids.

In this study, the research group proposed a new system in which the growth-factor secreting rat liver cells would be co-cultured or cultured together with the modified cyanobacteria, and the supernatant from this co-culture could then be used to promote muscle cell growth without serum. They found that co-culturing cyanobacteria with the rat liver cells resulted in a 30% reduction of lactate and over 90% reduction of ammonia. Additionally, the nutrients produced by the cyanobacteria were able to reduce the nutrient depletion by rat liver cells, resulting in an abundance of nutrients like glucose and pyruvate in the co-culture supernatant compared to the supernatant collected from where rat liver cells were grown alone.

When this co-culture supernatant was used to cultivate muscle cells, they found that the growth rate of muscle cells was three times higher than the growth seen when only rat liver cells were used. This demonstrates that co-culturing cyanobacteria significantly enhances the performance of the culture supernatant as a serum alternative and optimizes cell culture through waste upcycling.

“Our study provides a novel low cost, sustainable cell culture system with broad applicability in various fields involving cellular agriculture, such as cultured meat production, fermentation, bio-pharmaceutical production, and regenerative medicine. Further, as a technology for producing meat without killing animals, culturing animal cells with photosynthetic microorganisms could help address not only future food security challenges, but also ethical concerns and issues related to climate change,” concludes Shimizu.

***

Reference

Authors: Shanga Chu1,2, Yuji Haraguchi2, Toru Asahi1,3,4, Yuichi Kato5,6, Akihiko Kondo5,6,7, Tomohisa Hasunuma5,6,7 & Tatsuya Shimizu2

DOI: https://doi.org/10.1038/s41598-024-70377-8

Affiliations:

1Department of Advanced Science and Engineering, Waseda University

2Institute of Advanced Biomedical Engineering and Science, Tokyo Women’s Medical University

3Department of Life Science and Medical Bioscience, Waseda University

4Faculty of Science and Engineering, Waseda University

5Engineering Biology Research Center, Kobe University

6Graduate School of Science, Technology and Innovation, Kobe University

7Research Center for Sustainable Resource Science, RIKEN

About Waseda University

Located in the heart of Tokyo, Waseda University is a leading private research university that has long been dedicated to academic excellence, innovative research, and civic engagement at both the local and global levels since 1882. The University has produced many changemakers in its history, including nine prime ministers and many leaders in business, science and technology, literature, sports, and film. Waseda has strong collaborations with overseas research institutions and is committed to advancing cutting-edge research and developing leaders who can contribute to the resolution of complex, global social issues. The University has set a target of achieving a zero-carbon campus by 2032, in line with the Sustainable Development Goals (SDGs) adopted by the United Nations in 2015.

To learn more about Waseda University, visit https://www.waseda.jp/top/en

About Ms. Shanga Chu from Waseda University

Ms. Shanga Chu is currently a Ph.D. student at the School of Advanced Science and Engineering, Waseda University. She graduated from the Department of Applied Science and Engineering at the School of Engineering, Hokkaido University in March 2022. Her research work includes spontaneous nutrient cycling culture system by co-culturing microalgae and animal cells.

Funding information

This work was supported by the Cabinet Office, Government of Japan, Cross-ministerial Moonshot Agriculture, Forestry and Fisheries Research and Development Program, “Technologies for Smart Bio-industry and Agriculture” (funding agency: Bio-oriented Technology Research Advancement Institution).

END