As dairy farmers dwindle every year, the demand for high-quality milk remains steadfast, driving a surge in dairy farming. Although this shift improves efficiency, it makes managing the health of individual cows more challenging. Effective health management has thereby become a critical issue in the dairy industry. Early detection of abnormalities, swift diagnosis, prevention of disease spread, and maintaining proper breeding cycles are essential for desirable and stable milk production.

While there are invasive methods, like using mechanical devices attached to dairy cows for health monitoring, non-intrusive and non-contact techniques are preferred. These methods are less stressful for the cows, as they do not require any physical attachments, making them more suitable for everyday use on farms. These include advanced deep learning methods, such as camera-based tracking and image analysis. This approach is based on the idea that dairy cows often exhibit unusual behaviors and movement patterns due to illness, diseases, the estrus cycle, stress, or anxiety. By tracking individual movements using cameras—such as walking patterns, visits to feeding stations, and water consumption frequency—farmers can analyze cow behavior, enabling early prediction of diseases or health issues.

A team of researchers from Tokyo University of Science (TUS), Japan, led by Assistant Professor Yota Yamamoto from the Department of Information and Computer Technology, Faculty of Engineering, along with Mr. Kazuhiro Akizawa, Mr. Shunpei Aou, and Professor Yukinobu Taniguchi, has developed a novel location-based method using a multi-camera system to track cows across an entire barn. Their findings were made available online on December 4, 2024, and will be published in Volume 229 of Computers and Electronics in Agriculture on February 1, 2025.

The proposed method for tracking dairy cows in barns relies on location information rather than complicated image patterns. Dr. Yamamoto explains the advancements of their technique, “This is the first attempt to track dairy cows across an entire barn using multi-camera systems. While previous studies have used multiple cameras to track different species of cows, each camera typically tracks cows individually, often the same cow as a different one across cameras. Although some methods enable consistent tracking across cameras, they have been limited to two or three cameras covering only a portion of the barn.”

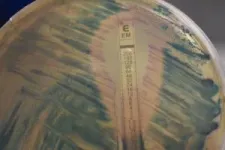

The system relies on overlapping camera views to accurately and consistently track dairy cows as they move from one camera to another, enabling seamless tracking across multiple cameras. By carefully managing the number of cameras and their fields of view, the system can minimize the negative effects of obstacles like walls or pillars, which can cause fragmented camera overlaps in barns with complex layouts. This approach overcomes common challenges, such as the cows’ speckled fur patterns and distortions caused by camera lenses, which often make traditional tracking methods less accurate.

In tests using video footage of cows moving closely together in a barn, this method achieved about 90% accuracy in tracking the cows, measured through Multi-Object Tracking Accuracy, and around 80% Identification F1 score for identifying each individual cow. This marks a significant improvement over conventional methods, which struggled with accuracy, especially in crowded or complex barn environments. It also performs well in different situations, whether the cows are moving slowly or standing still, and also addressed the challenge of cows lying down by adjusting the cow height parameter to 0.9 meters, lower than a standing cow's height. This adjustment improved tracking accuracy despite posture changes.

“This method enables optimal management and round-the-clock health monitoring of dairy cows, ensuring high-quality milk production at a reasonable price,” says Dr. Yamamoto. In the future, the team plans to automate the camera setup process to simplify and speed up the installation of the system in various barns. They also aim to enhance the system’s ability to detect dairy cows that may be showing signs of illness or other health issues, helping farmers monitor and manage the health of their herds more efficiently.

***

Reference

DOI: 10.1016/j.compag.2024.109668

About The Tokyo University of Science

Tokyo University of Science (TUS) is a well-known and respected university, and the largest science-specialized private research university in Japan, with four campuses in central Tokyo and its suburbs and in Hokkaido. Established in 1881, the university has continually contributed to Japan's development in science through inculcating the love for science in researchers, technicians, and educators.

With a mission of “Creating science and technology for the harmonious development of nature, human beings, and society,” TUS has undertaken a wide range of research from basic to applied science. TUS has embraced a multidisciplinary approach to research and undertaken intensive study in some of today's most vital fields. TUS is a meritocracy where the best in science is recognized and nurtured. It is the only private university in Japan that has produced a Nobel Prize winner and the only private university in Asia to produce Nobel Prize winners within the natural sciences field.

Website: https://www.tus.ac.jp/en/mediarelations/

About Assistant Professor Yota Yamamoto from Tokyo University of Science

Yota Yamamoto is an Assistant Professor at the Department of Information and Computer Technology, Faculty of Engineering, at Tokyo University of Science. He earned his Ph.D. in Engineering from Chiba University Graduate School of Science and Engineering. His research interests include high-performance computing, special-purpose computers, FPGA, GPGPU, machine learning, image processing, holography, three-dimensional displays, and three-dimensional measurements. Dr. Yamamoto has authored over 20 papers in these fields, which have collectively been cited more than 300 times.

Funding information

Financial support was provided by Tsuchiya Manufacturing. Co. Ltd.

END