(Press-News.org) Researchers have flipped traditional 3D printing to create some of the most intricate biomedical structures yet, advancing the development of new technologies for regrowing bones and tissue.

The emerging field of tissue engineering aims to harness the human body's natural ability to heal itself, to rebuild bone and muscle lost to tumours or injuries.

A key focus for biomedical engineers has been the design and development of 3D printed scaffolds that can be implanted in the body to support cell regrowth.

But making these structures small and complex enough for cells to thrive remains a significant challenge.

Enter a RMIT University-led research team, collaborating with clinicians at St Vincent's Hospital Melbourne, Australia, who have overturned the conventional 3D printing approach.

Watch and embed the timelapse video

Instead of making the bioscaffolds directly, the team 3D printed moulds with intricately-patterned cavities then filled them with biocompatible materials, before dissolving the moulds away.

Using the indirect approach, the team created fingernail-sized bioscaffolds full of elaborate structures that, until now, were considered impossible with standard 3D printers.

Lead researcher Dr Cathal O'Connell said the new biofabrication method was cost-effective and easily scalable because it relied on widely available technology.

"The shapes you can make with a standard 3D printer are constrained by the size of the printing nozzle - the opening needs to be big enough to let material through and ultimately that influences how small you can print," O'Connell, a Vice-Chancellor's Postdoctoral Fellow at RMIT, said.

"But the gaps in between the printed material can be way smaller, and far more intricate.

"By flipping our thinking, we essentially draw the structure we want in the empty space inside our 3D printed mould. This allows us to create the tiny, complex microstructures where cells will flourish."

Versatile technique

O'Connell said other approaches were able to create impressive structures, but only with precisely-tailored materials, tuned with particular additives or modified with special chemistry.

"Importantly, our technique is versatile enough to use medical grade materials off-the-shelf," he said.

"It's extraordinary to create such complex shapes using a basic 'high school' grade 3D printer.

"That really lowers the bar for entry into the field, and brings us a significant step closer to making tissue engineering a medical reality."

The research, published in Advanced Materials Technologies, was conducted at BioFab3D@ACMD, a state-of-the-art bioengineering research, education and training hub located at St Vincent's Hospital Melbourne.

Co-author Associate Professor Claudia Di Bella, an orthopedic surgeon at St Vincent's Hospital Melbourne, said the study showcases the possibilities that open up when clinicians, engineers and biomedical scientists come together to address a clinical problem.

"A common problem faced by clinicians is the inability to access technological experimental solutions for the problems they face daily," Di Bella said.

"While a clinician is the best professional to recognise a problem and think about potential solutions, biomedical engineers can turn that idea into reality.

"Learning how to speak a common language across engineering and medicine is often an initial barrier, but once this is overcome, the possibilities are endless."

Future treatment toolkit

Currently there are few treatment options for people who lose a significant amount of bone or tissue due to illness or injury, making amputation or metal implants to fill a gap common outcomes.

While a few clinical trials of tissue engineering have been conducted around the world, key bioengineering challenges still need to be addressed for 3D bioprinting technology to become a standard part of a surgeon's toolkit.

In orthopedics, a major sticking point is the development of a bioscaffold that works across both bone and cartilage.

"Our new method is so precise we're creating specialised bone and cartilage-growing microstructures in a single bioscaffold," O'Connell said.

"It's the surgical ideal - one integrated scaffold that can support both types of cells, to better replicate the way the body works."

Tests with human cells have shown bioscaffolds built using the new method are safe and non-toxic.

The next steps for the researchers will be testing designs to optimise cell regeneration and investigating the impact on cell regrowth of different combinations of biocompatible materials.

Step-by-step: How to reverse print a bioscaffold

The new method - which researchers have dubbed Negative Embodied Sacrificial Template 3D (NEST3D) printing - uses simple PVA glue as the basis for the 3D printed mould.

Once the biocompatible material injected into the mould has set, the entire structure is placed in water to dissolve the glue, leaving just the cell-nurturing bioscaffold.

Study first author, PhD researcher Stephanie Doyle, said the method enabled researchers to rapidly test combinations of materials to identify those most effective for cell growth.

"The advantage of our advanced injection moulding technique is its versatility," Doyle said.

"We can produce dozens of trial bioscaffolds in a range of materials - from biodegradable polymers to hydrogels, silicones and ceramics - without the need for rigorous optimisation or specialist equipment.

"We're able to produce 3D structures that can be just 200 microns across, the width of 4 human hairs, and with complexity that rivals that achievable by light-based fabrication techniques.

"It could be a massive accelerator for biofabrication and tissue engineering research."

INFORMATION:

The research was supported by the St Vincent's Hospital Melbourne Research Endowment Fund, Victorian Medical Research Acceleration Fund, NHMRC-MRFF Investigator Grant and Australian Technology Network of Universities Industry Doctoral Training Centre.

ACMD's collaborative approach brings together leading tertiary institutions including RMIT University, the University of Melbourne, Swinburne University of Technology and the University of Wollongong, research institutes and St Vincent's Hospital Melbourne, where the centre is based, to take on today's toughest healthcare challenges.

'Printing between the lines: Intricate biomaterial structures fabricated via Negative Embodied Sacrificial Template 3D (NEST3D) Printing', with RMIT co-authors Dr Anita Quigley and Professor Elena Pigorova, and collaborators from University of Melbourne (Dr Serena Duchi, Dr Carmine Onofrillo), is published in Advanced Materials Technologies (DOI: 10.1002/admt.202100189).

A new study has shown that effective opioid-sparing anaesthesia with dexmedetomidine can be guided with NOL pain monitoring technology (Medasense, Israel). The study showed that the NOL monitor is able to detect the effect of dexmedetomidine on the patient's pain response and enable administration of less intraoperative opioids.

Patients undergoing anaesthesia for surgical procedures are traditionally treated with opioids (e.g., remifentanil) to manage intraoperative pain. But clinicians are progressively seeking to reduce opioid use by introducing multimodal analgesia, a technique that involves a combination of medications that often includes a central ...

Professor UEYAMA Takehiko (Biosignal Research Center, Kobe University) and the inner ear research group (Kyoto Prefectural University of Medicine) have identified the cell types in the inner ear cochlea (*1) responsible for the production of superoxide (Nox3*2-expressing cells). They achieved this by using genetically modified mice that they developed. The researchers discovered that these superoxide-producing cells increase in number in response to aging, noise damage, and ototoxic drugs, thus causing age-related, noise-induced and drug-induced hearing loss. In addition, they were able to suppress the onset of these three types of ...

HERSHEY, Pa. -- Screening and testing for sexually transmitted infections (STIs) decreased by 63% for men and 59% for women during the early months of the COVID-19 pandemic, according to a new study led by Penn State and Quest Diagnostics researchers. The researchers said this may be the result of restrictions placed on direct patient care and shifts to telehealth and could lead to a possible future surge in STI cases.

This is the first national study to explore the impact of the pandemic on STIs since the Centers for Disease Control and Prevention ...

Computational tools are indispensable in almost all scientific disciplines. Especially in cases where large amounts of research data are generated and need to be quickly processed, reliable, carefully developed software is crucial for analyzing and correctly interpreting such data. Nevertheless, scientific software can have quality quality deficiencies. To evaluate software quality in an automated way, computer scientists at Karlsruhe Institute of Technology (KIT) and Heidelberg Institute for Theoretical Studies (HITS) have designed the SoftWipe tool.

"Adherence to coding standards is rarely considered in scientific software, although it can even lead to incorrect scientific results," says ...

BOSTON - Physical activity that conforms to medical and health association guidelines is associated with a lower risk of atrial fibrillation (Afib) and stroke, according to a study by researchers at Massachusetts General Hospital (MGH), who analyzed nearly 100,000 individuals equipped with wrist-worn accelerometers to measure their movement. The researchers' findings suggest that data from wearables, including a new generation of devices with sensors that allow for Afib detection, could provide an opportunity for the public health community to promote moderate physical activity as an effective way to improve health outcomes. The study ...

Digital medicine is opening up entirely new possibilities. For example, it can detect tumors at an early stage. But the effectiveness of new AI algorithms depends on the quantity and quality of the data used to train them.

To maximize the data pool, it is customary to share patient data between clinics by sending copies of databases to the clinics where the algorithm is being trained. For data protection purposes, the material usually undergoes anonymization and pseudonymization processes - a procedure that has also come in for criticism. "These processes have often proven inadequate in terms of protecting patients' health data," says Daniel Rueckert, ...

From shamans and mystics to cult leaders and divine kings, why have people throughout history accorded high status to people believed to have supernatural powers?

According to a study led by researchers from the University of Oxford, this tendency to attribute social dominance to such individuals is rooted in early development.

As part of the study, 48 infants aged 12 to 16 months watched a series of animated videos in which two characters competed for a reward. In each scenario, one character displayed physically counterintuitive methods of making ...

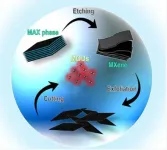

In a new publication from Opto-Electronic Advances; DOI https://doi.org/10.29026/oea.2021.200077, Researchers led by Professor Jeongyong Kim at the Department of Energy Science, Sungkyunkwan University, Suwon, Republic of Korea review light-emitting MXene quantum dots.

MXenes have found wide-ranging applications in energy storage devices, sensors, catalysis, etc. owing to their high electronic conductivity and wide range of optical absorption. However, the absence of semiconducting MXenes has limited their applications related to light emission.

Extensively reviewing current relevant research, the authors summarise recent advances in MXene quantum dot (MQD) research on the synthesis, optical properties and applications of MQDs as light emitting quantum materials. Research ...

Graphene is an ultrathin material characterized by its ultrasmall bending modulus, superflimsiness. Now the researchers at the Nanoscience Center of the University of Jyväskylä have demonstrated how an experimental technique called optical forging can make graphene ultrastiff, increase its stiffness by several orders of magnitude. The research was published in npj 2D Materials and Applications in May 2021.

Graphene is an atomically thin carbon material loaded with excellent properties, such as large charge carrier mobility, superb thermal conductivity, and high ...

When it comes to distinguishing a healthy cell from an infected one that needs to be destroyed, the immune system's killer T cells sometimes make mistakes.

This discovery, described today in eLife, upends a long-held belief among scientists that T cells were nearly perfect at discriminating friend from foe. The results may point to new ways to treat autoimmune diseases that cause the immune system to attack the body, or lead to improvements in cutting-edge cancer treatments.

It is widely believed that T cells can discriminate perfectly between infected cells and healthy ones based on how tightly they are able to bind to molecules called antigens ...