Different from traditional alloys, BMGs exhibit a unique atomic arrangement characterized by short-range order and long-range disorder at the atomic level. Such atomic structure leads to the absence of defects such as grain boundaries and dislocations, resulting in exceptional mechanical properties. The promising properties of BMGs have rapidly positioned them as a new class of structural and functional materials, showing great application potential in various fields including structural, energy and chemical engineering. In order to facilitate their engineering applications, research has reported their cutting characteristics from various aspects, including optimizing cutting tools, developing suitable machining parameters, and revealing chip formation mechanisms. However, few studies were focused on the effects of tool geometric parameters on chip morphology. Since chip morphology reflects the state of cutting process and the chip formation process will affect the cutting characteristics, it is essential to fill this research gap.

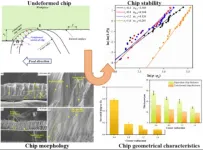

Recently, an academic team led by Shunhua Chen from Hefei University of Technology, China reported the influence of tool corner radius on the chip geometrical characteristics of machining Zr-based BMGs. The Chip morphology under various tool corner radii was analyzed, which offered guidance for the selection of tool geometric parameters to achieve better surface quality and to expand the engineering applications of BMGs.

The team published their work in Journal of Advanced Manufacturing Science and Technology on Sep 5, 2024.

“In this work, the effect of corner radius on the chip formation of a Zr-based BMG was investigated. The shape and morphology of the chips in terms of chip shape, back surface morphology and serrated chip morphology were analyzed. Continuous ribbon-shaped chips were found during turning. Due to the low plasticity of BMG, chips were less curled than those of comparative materials. Burrs were observed due to the chip tearing and dropping off layer by layer along multiple scratches, and the burr formation differed significantly with different corner radii.” said Shunhua Chen, a full professor at School of Mechanical Engineering at Hefei University of Technology (China).

“As the corner radius increased, more shear bands developed, showing an increase in serrated frequency and more secondary shear bands within individual serrated sections. The formation of BMG chips was associated with multiple shear behaviors, including shearing in the primary shear zones (PSZs), multi-step shearing after the PSZs fracture, and secondary shearing within the individual serrated sections.” said Haidong Yang, associate professor at School of Mechanical Engineering at Hefei University of Technology (China), a senior expert whose research interests focus on the field of cutting tools.

The analysis of the stability of serrated chip formation during machining can help better understand the chip formation mechanisms, predict and regulate the machining process, and thereby improve machining efficiency, accuracy, and reliability, which was of great significance. “The stability of the serrated chip formation was expressed by three-parameter Weibull modulus. The Weibull modulus of the inclination angles of serrated chips increased with the increase of corner radius, indicating the transition of the serrated chip formation from unstable to stable, which was conducive to the formation of better machined surface. The findings gave more insights into the machining process of Zr-based BMGs, and open a new avenue to characterize the chips, establishing a good foundation for the practical application of BMGs and their parts.” said Shunhua Chen.

For the machining of BMGs, there still exist three aspects worthy of further investigations in future, i.e., the parametric characterization of chips, the physical process of chip formation and the effect of chip formation behavior on surface quality.

Other contributors include Libao Zhang, Haodong Li, Junsheng Zhang and Huohong Tang from the Hefei University of Technology, China.

This work was mainly supported by the Fundamental Research Funds for the Central Universities of China (Grant no. PA2024GDSK0060; PA2023GDSK0075) and the Ningbo Science and Technology Innovation 2025 Major Project (Grant no. 2022Z047).

About Author

Prof. Shunhua Chen, the group leader, is a full professor in School of Mechanical Engineering, Hefei University of Technology. He is the head of the Department of Mechanical Manufacturing Engineering. His research interests are mainly in the area of processing and manufacturing of advanced alloys, such as bulk metallic glasses (BMGs) and high entropy alloys (HEAs), including machining, EDM, ECM, data-driven optimization, microstructure and mechanical properties, and the development of advanced alloys. He has published over 100 research papers in prestigious international journals and received more than 30 Chinese national invention patents in recent years.

Dr. Haidong Yang, the first author, is an associate professor of Hefei University of Technology, and a council member of the China Metal Cutting Tool Engineering Association. His primary research areas include cutting tools, material procecing, and advanced manufacturing technologies.

About Journal of Advanced Manufacturing Science and Technology

Journal of Advanced Manufacturing Science and Technology (JAMST) is an open-access and peer-reviewed journal that was launched by Dalian University of Technology and Engineering Research Center of Advanced Manufacturing Technology for Aero Engine, Ministry of Education, Northwestern Polytechnical University in 2021. The journal is published by Tsinghua University Presss.

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END