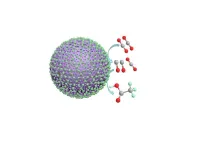

Relays are extensively utilized in accelerators, satellites, rockets, and various advanced technology sectors. They play crucial roles in signal transmission, long-distance control implementation, and protection circuits, directly impacting the safety of aerospace and defense equipment systems. The selection of electrical contact material in a relay is crucial for its performance. Arc discharge, characterized by high temperature, heat, and energy, is a common occurrence during operation. Consequently, the arc erodes the electric contact material, causing craters, spattered particles, compositional changes, and a decrease in performance. Traditionally used silver-based electrical contact material, such as AgCdO and AgSnO2, suffer from chromium toxicity or poor wettability and severe temperature rise. Therefore, it is necessary to find a new reinforcement phase material to replace CdO and SnO2 materials. MAX phase materials are a type of ceramic material known for their good electrical conductivity, and the arc erosion performance of MAX phase enhanced silver based electrical contact materials has been recently investigated.

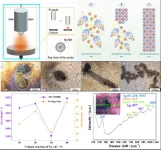

Recently, a team of material scientists led by Xiaochen Huang from Bengbu University, China first reported the synthesis, microstructure, physical properties (relative density, hardness, and electrical conductivity) and arc erosion performance of Ag-Ta2AlC composite material. A comparative analysis of arc erosion properties was conducted of Ag-Ta2AlC composites with varying compositions. Additionally, the microstructural and chemical changes in Ag-Ta2AlC composites were observed and recorded experimentally. The mechanism of arc erosion and the formation of morphology was systematically explained.

The team published their work in Journal of Advanced Ceramics on July 9, 2024.

“In this report, Ag-Ta2AlC composites with volume fractions of 10%, 20%, 30%, and 40% were fabricated by hot pressing sintering. The relative density of Ag- 10 vol.% Ta2AlC composite material was 98.2%. As the Ta2AlC content increased, the relative density of Ag-Ta2AlC composite material gradually decreased. The hardness initially increased and then decreased. The Ag- 30 vol.% Ta2AlC composite exhibited the highest hardness at 97.4 HV” said Xiaochen Huang, Associate Professor at Bengbu University (China), a researcher whose research interests focus on the field of Ag based electrical contact material.

“The Ag- 30 vol.% Ta2AlC composite material exhibited the lowest arc energy (3.395 kJ) and shortest arcing time (33.26 ms). Additionally, the arc was dispersed on the surface of Ag- 30 vol.% Ta2AlC composite material, preventing concentrated arc erosion and demonstrating higher arc erosion resistance among the four components” said Xiaochen Huang.

“The surface atoms of the Ag-Ta2AlC composite absorbed energy, which exceeded the work function of Ag and Ta2AlC, resulting in their ionization. Ionized oxygen atoms combined with Ta and Al ions to form Ag2O, AgO, Ta2O5, and Al2O3” said Xiaochen Huang.

However, the transition boundary from the metallic to gaseous phase was found to be closely related to the arc voltage, air pressure, gas types, and materials. Considering complexity of factors influencing the arc transition from the metallic to the gaseous phase, it was necessary to further explore the arc transition of Ag-Ta2AlC under air conditions.

Other contributors include Xiaochen Huang, Liang Li, Jinlong Ge from the School of Material and Chemical Engineering at Bengbu University in Bengbu, China; Hao Zhao from the School of chemical and materials engineering, Anhui Science and Technology University in Bengbu, China; Zijue Zhou from School of Chemistry and Materials Engineering at Huainan Normal University in Huainan, China.

The work was financially supported by the Nature Science Foundation of Anhui Province, China (2208085ME104, 1908085QE218), the University Natural Science Research Project of Anhui Province (KJ2021ZD0141, 2022AH051589), Cultivation Programme for the Outstanding Young Teachers of Anhui Province (YQYB2023054),and Guiding Science and Technology Plan Project in Huainan City (2023017).

About Author

Xiaochen Huang holds a BSc in metals from Hefei University of Technology, and a Ph.D. in material science from Hefei University of Technology. She is an Associate Professor at Bengbu University in Bengbu, China.

Huang is mainly engaged in the research on the preparation and properties of sliding electrical contact materials, and has presided over four provincial scientific research projects. She has published more than 20 papers in. She has published more than 20 papers in domestic and international high level journals such as Script Materialia, Journal of Advanced Ceramics, Materials Letters, Journal of Alloys and Compounds, Science China Technological Sciences and Ceramics International et al. She has presided two provincial teaching research projects, won two third prizes for teaching achievements in Anhui Province, and guided students to preside two national innovation and entrepreneurship projects for university students.

About Journal of Advanced Ceramics

Journal of Advanced Ceramics (JAC) is an international academic journal that presents the state-of-the-art results of theoretical and experimental studies on the processing, structure, and properties of advanced ceramics and ceramic-based composites. JAC is Fully Open Access, monthly published by Tsinghua University Press, and exclusively available via SciOpen. JAC’s 2023 IF is 18.6, ranking in Top 1 (1/31, Q1) among all journals in “Materials Science, Ceramics” category, and its 2023 CiteScore is 21.0 (top 5%) in Scopus database. ResearchGate homepage: https://www.researchgate.net/journal/Journal-of-Advanced-Ceramics-2227-8508

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END