Radomes and wave-transmitting antenna windows are critical structural components in aircraft, protecting radar antennas from external interference while ensuring reliable communication. Currently, the most widely used wave-transmitting materials are ceramics based on oxides and nitrides. Si3N4 ceramics, with their high melting point and superior mechanical properties, are considered promising candidates for hypersonic vehicle applications. However, the dielectric and thermal insulation properties of dense Si3N4 ceramics need improvement to meet the precise guidance and thermal protection demands of high-speed flight. By adjusting the microstructure, it is possible to enhance the dielectric, mechanical, and thermal properties of wave-permeable materials. As such, porous Si3N4 ceramics are pivotal in the development of radomes and antenna windows for hypersonic aircraft, which must endure extreme temperatures and stresses while maintaining low dielectric constants for effective radar functionality. Traditionally, balancing mechanical strength with wave-transmission efficiency has been a challenge, requiring innovative solutions to improve both aspects.

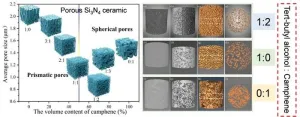

Recently, a team of material scientists led by Dr. Zhilin Tian and Bin Li from Sun Yat-sen University in China developed a porous Si3N4 ceramic with uniform, fine structures using a dual-solvent templating and freeze-casting method. This approach enables precise control over pore size and structure—key factors influencing the performance of high-temperature wave-transparent materials. Conventional methods like direct foaming, gel casting, and organic template impregnation often fail to achieve the necessary uniformity and regularity in pore structure. However, the new method can effortlessly transform anisotropic prismatic pores into isotropic spherical pores. This innovation leads to a synergistic enhancement of mechanical, thermal, and dielectric properties in porous Si3N4 ceramics.

The team published their work in the Journal of Advanced Ceramics on August 26, 2024.

“In this study, we developed porous Si3N4 ceramics with uniform pore structures using a dual-solvent templating and freeze-casting method. The resulting ceramics have a porosity of 56% and exhibit impressive mechanical properties, with bending and compressive strengths of 95±14.8 MPa and 132±4.5 MPa, respectively,” explained Professor Zhilin Tian. “The dual-solvent system enriches the diversity of pore structures, which is closely tied to the solvent ratio. As the tert-butyl alcohol content decreases, the pore structure transitions from prismatic to spherical. Moreover, with increased camphene content, the pore diameter initially decreases before increasing again. When the solvent ratio is 1:2, the average pore diameter reaches its minimum, due to competition between the solvent crystals for growth space. More tert-butyl alcohol results in larger crystal and pore sizes, while reduced tert-butyl alcohol allows smaller camphene crystals to dominate, leading to smaller pores.”

“Our dual-solvent templating method offers unprecedented control over pore size and structure, which are critical for creating high-performance ceramics for aerospace applications,” said Professor Tian. “The combination of tert-butyl alcohol and camphene as templates allows us to achieve isotropic spherical pores, greatly enhancing both mechanical strength and thermal properties.” He further elaborated, “The competition between solvent crystals helps achieve optimal pore size, leading to improved crack deflection and energy absorption under high-speed flight conditions.”

This study lays the groundwork for further advancements in wave-transparent materials. According to Professor Tian, the next steps include scaling up the production process and fine-tuning the material’s properties to meet the specific demands of various aerospace applications. “Our ultimate goal is to develop a class of ceramics that can be utilized in a wide range of extreme environments.

This work was financially supported by the National Natural Science Foundation of China (Grant No. 52202078), the Leading Talent Project of the National Special Support Program (2022WRLJ003), Guangdong Basic and Applied Basic Research Foundation for Distinguished Young Scholars (Grant No. 2021B1515020083), and Guangdong Basic and Applied Basic Research Foundation (Grant Nos. 2021A1515110293 and 2022A1515012201).

About Author

Tian Zhilin earned his bachelor's degree from Central South University and his PhD in Materials Science from the Institute of Metal Research, Chinese Academy of Sciences. He is currently an associate professor at the School of Materials Science, Sun Yat-sen University. Dr. Tian has published more than 40 articles in prestigious journals such as Acta Materialia, Scripta Materialia, Corrosion Science, and Journal of Advanced Ceramics.

Li Bin is a professor at the School of Materials Science, Sun Yat-sen University. His research primarily focuses on aerospace composite materials and intelligent sensing materials. He has authored the first monograph in the field of nitride aerospace wave-transmitting materials and has published 150 academic papers.

About Journal of Advanced Ceramics

Journal of Advanced Ceramics (JAC) is an international academic journal that presents the state-of-the-art results of theoretical and experimental studies on the processing, structure, and properties of advanced ceramics and ceramic-based composites. JAC is Fully Open Access, monthly published by Tsinghua University Press, and exclusively available via SciOpen. JAC’s 2023 IF is 18.6, ranking in Top 1 (1/31, Q1) among all journals in “Materials Science, Ceramics” category, and its 2023 CiteScore is 21.0 (top 5%) in Scopus database. ResearchGate homepage: https://www.researchgate.net/journal/Journal-of-Advanced-Ceramics-2227-8508

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END