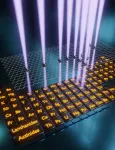

Oak Ridge National Laboratory scientists demonstrated that an electron microscope can be used to selectively remove carbon atoms from graphene's atomically thin lattice and stitch transition-metal dopant atoms in their place.

This method could open the door to making quantum building blocks that can interact to produce exotic electronic, magnetic and topological properties.

This is the first precision positioning of transition-metal dopants in graphene. The produced graphene-dopant complexes can exhibit atomic-like behavior, inducing desired properties in the graphene.

"What could you build if you could put any atoms exactly where you want? Just about anything," ORNL's Ondrej Dyck said. He co-led the study with Stephen Jesse at ORNL's Center for Nanophase Materials Sciences.

"If a lot of these quantum building blocks get together, they can start to act in a correlated manner, which is when really exciting properties begin to emerge," Jesse said. The scientists plan to make arrays of interacting quantum building blocks to investigate emergent properties.

Media contact:

Dawn Levy,

865.202.9465,

levyd@ornl.gov

Image: https://www.ornl.gov/sites/default/files/2021-02/quantum-building-blocks_0.jpg

Caption: Transition metals stitched into graphene with an electron beam form promising quantum building blocks. Credit: Ondrej Dyck, Andrew Lupini and Jacob Swett/ORNL, U.S. Dept. of Energy

Neutrons - Hard diamonds, high pressures

Researchers at Oak Ridge National Laboratory's Spallation Neutron Source have developed a diamond anvil pressure cell that will enable high-pressure science currently not possible at any other neutron source in the world.

Using the SNAP instrument, the team measured high-quality powder diffraction data on a material above 120 gigapascals, shattering the previously held record of 62 GPa for meaningful structural data.

What's more, the tiny submillimeter-sized sample used in the experiment is likely the smallest neutron sample ever measured and yet is also one of the largest powder samples ever held at such a high static pressure.

While scientists have used X-ray powder diffraction at such pressures for decades, it was previously not possible using neutrons.

"This breakthrough enables new studies on the structures of high-pressure super-hydrides that exhibit room-temperature superconductivity. It even enables investigations into materials at earth-core pressure conditions," said ORNL's Bianca Haberl.

Media contact:

Jeremy Rumsey,

865.576.2038,

rumseyjp@ornl.gov

Image: https://www.ornl.gov/sites/default/files/2021-02/SNAP%20pressure%20cell%202021-P00978RR.jpg

Caption: ORNL researchers Reinhard Boehler, left, and Bianca Haberl demonstrate the improved pressure cell developed by Boehler. The device uses two gem-quality synthetic opposing diamonds to exert extreme pressures on materials. Credit: Genevieve Martin/ORNL, U.S. Dept. of Energy

Image: https://www.ornl.gov/sites/default/files/2021-02/SNAP%20pressure%20cell.jpg

Caption: The pressure cell uses two gem-quality synthetic opposing diamonds to exert extreme pressures on materials, providing fundamental insights into materials that only neutrons can reveal. Credit: Genevieve Martin/ORNL, U.S. Dept. of Energy

Ecology - After the burn

An Oak Ridge National Laboratory research team discovered that aspen saplings emerging after wildfire have less diverse microbiomes and more pathogens in their leaves, providing new insights about how fire affects ecosystem recovery.

This study demonstrated, for the first time, the indirect impacts of fire on microbes throughout plant structures.

"The leaves of these saplings never experienced fire, but we were able to show differences in their microbiome compared to saplings from unburned areas," ORNL's Chris Schadt said. "Since aspen saplings are clonally derived from the surviving roots, we had thought the leaves might be populated by organisms that were drawn up through the common root. That didn't happen."

The ORNL team plans to further study how microbes repopulate plants after fire. Additional analysis could inform ways to speed vegetative regeneration and the host of benefits that come with healthy forests, from clean water to biodiversity to carbon capture.

Media contact:

Kim Askey,

865.576.2841,

askeyka@ornl.gov

Image: https://www.ornl.gov/sites/default/files/2021-02/2019-09-12_09.10.25_panorama.jpg

Caption: Saplings in an aspen grove recovering from wildfire have more fungal pathogens in their leaves than the original trees. Credit: Chris Schadt/ORNL, U.S. Dept. of Energy

Image: https://www.ornl.gov/sites/default/files/2021-02/2019-09-12_09.27.18_copy.jpg

Caption: Aspen saplings begin to emerge after a fire in June of 2019. Credit: Chris Schadt/ORNL, U.S. Dept. of Energy

Manufacturing - Quick cooling tooling

A team of Oak Ridge National Laboratory researchers demonstrated that an additively manufactured hot stamping die - a tool used to create car body components - cooled faster than those produced by conventional manufacturing methods, which could lead to reduced manufacturing costs and production time.

In collaboration with industry partners Lincoln Electric and DTS, they used a gas metal arc welding-based additive technology to print the die for a B-pillar or vertical roof support structure for a sport utility vehicle. The production method allowed for the entire body of the die to be created as one monolithic part.

"With conventional methods, the dies are manufactured by drilling cooling ports in one-foot-long blocks of steel, then assembling, machining the blocks and sealing, and they take 20 days to produce," ORNL's Andrzej Nycz said. "We machined and tested the additively manufactured die in eight days and showed more uniform temperature distribution and 20% improvement in the cooling rate."

Media contact:

Jennifer Burke,

865.414.6835,

burkejj@ornl.gov

Image: https://www.ornl.gov/sites/default/files/2021-02/Hot_stamping_die.jpg

Caption: ORNL researchers used gas metal arc welding additive technology to print the die for a B-pillar or vertical roof support structure for a sport utility vehicle, demonstrating a 20% improvement in the cooling rate. Credit: ORNL, U.S. Dept. of Energy

Sensors - Printing on the fly

A method developed at Oak Ridge National Laboratory to print high-fidelity, passive sensors for energy applications can reduce the cost of monitoring critical power grid assets.

The sensors use surface acoustic waves, or SAWs, which can pick up changes in temperature, pressure and the presence of gases. In search of a simpler, cheaper alternative to sensors that require elaborate assembly in a clean room, ORNL researchers developed a method to print SAW sensors on substrates of lithium niobate crystal using nanoparticle inks.

The scientists demonstrated that the sensor features can be printed at a resolution of about 10 micrometers, which increases their operating frequency and sensitivity. Ongoing research aims to reach 1 micrometer resolution and to test the sensors in both a simulated nuclear plant application and on essential grid components such as transformers.

"The sensors are low cost, easy to deploy and customizable, and you can make them on the fly," said ORNL's Tim McIntyre.

Media contact:

Stephanie Seay,

865.576.9894,

seaysg@ornl.gov

Image 1: https://www.ornl.gov/sites/default/files/2021-02/SAW%20sensors%202021-P01086.jpg

Image 2: https://www.ornl.gov/sites/default/files/2021-02/SAW%20sensors%202021-P01084.jpg

Caption: ORNL researchers are developing a method to print low-cost, high-fidelity, customizable sensors for monitoring power grid equipment. Credit: Carlos Jones/ORNL, U.S. Dept. of Energy

INFORMATION: