A research paper by scientists at the Beijing Institute of Technology and University of Lancaster displayed a recent advancement of using fuel explosion as the power of source to achieve the rapid and powerful motion for the medium-size robots.

The new research paper, published in the journal Cyborg and Bionic Systems, provided a new kind of actuation system for the robotic system, providing a promising patentability to largely improve the working length of the conventional medium-size robotic systems.

“Achieving the rapid and fast motion of the medium-size robot has been a challenging task for many years, …” explained by the author Nan Ma, who works at Lancaster University (UK) and leads this interesting research.

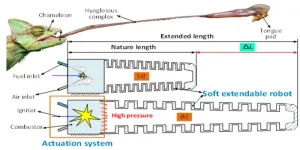

In recent years, different kinds of soft robots have been developed to satisfy the requirements of the varying applications. These soft material-based robotic systems have many advantages over the traditional rigid ones, such as the improved range of motion (ROM), better adaptability in unstructured areas, reduced cost and lower weight. The hyperelastic materials (e.g., elastomers) are normally adopted to support the motion of the soft robotic systems. For example, a wide range of soft robotics have been developed in recent years to mimic the motion of the nature animals (e.g., Multigait soft robot, Elephant’s trunk manipulator), aiming to conduct the tasks in the unstructured environment and terrain exploration by their multiple degree of freedom (DoF) bending capability. However, their capability for the long-distance and high-speed linear motion is rather constrained by their structure (e.g., constructed by multiple bending units) and actuation system (e.g., motor or pressurized air). Therefore, novel soft robots that can achieve the long-distance and rapid linear reaching is desired to develop the robotic system with advanced functions (e.g., the prey strategy of chameleon with an extendable tongue).

Also relevant to the actuation, different actuation methods have been studied over the past decades, including the electroactive polymer actuators, shape memory alloy (SMA) actuators, and pneumatic actuators. For example, the electroactive polymer actuators can reduce the energy consumption and improve the expansion efficiencies. The SMA actuators can reduce the weight and dimension of the system. The pneumatic actuation can provide high actuating force. For the abovementioned actuators, ether due to the bulk dimension, or the slow response, they are not suitable to be combined with the soft robots to develop the advanced extendable robotic system, where the quick response, compact dimension and powerful output are required. Promisingly, the explosion-based actuator can self-regulate the actuation pressure using the chemical decomposition of hydride in a closed space, where the high force and linear output motion can be achieved. This actuator has the high force to weight ratio due to its simple structure and powerful output, where the complex transmission mechanism, energy accumulation mechanism and energy release trigger mechanism can be omitted, which is the great advantage to reduce the overall weight of the system. Thanks to the abovementioned advantages of the explosion-based actuation system, it is selected as the actuation system to be combined with the developed linear motion soft robot to achieve the fast and long-distance motion.

Another challenge is how to design the soft robots that can be powered by the explosion to achieve the linear motion, as the explosive process coupled with the energy conversion processes (e.g., chemical dynamics, gas-phase dynamics, fluid dynamics processes), which are critical to the successful working of system. To solve this problem, the special design principles are proposed by the researcher. For example, Michael T. Tolley presented an untethered soft-bodied robot using a combination of pneumatic and explosive actuators to execute directional jumping manoeuvres. Robert F. Shepherd demonstrated the rapid actuation of pneu-nets using a chemical reaction to generate explosive bursts of pressure. However, to the best knowledge of the author, no soft robots powered by the explosion can realize the long-distance and high-speed linear motion.

“To address the aforementioned challenges of the soft robots to achieve the long-distance and high-speed linear motion, a novel explosion-based soft robot is proposed,” said by Ma, explaining why this interesting work has been launched and what the procedures have been involved to making the working of the new robotic system. He said, to support and predict the performance of the explosion-based soft robot, a new detail dynamic model, which can be used to quantitatively predict the energy generated by the explosion and predict the deformation of the soft robot is constructed. Further, the change of working fluid (molecular numbers) and some unavoidable and influential factors (e.g., heat transfer loss, specific heat and incomplete combustion) are also calculated. At last, the performance of the explosion-based soft robot to achieve the axial extension is tested, which is further used to verify the dynamic model developed in this paper. The results show that the developed model can be validated by the experimental results, which can provide an efficient way to guide the structure design of the system in the initial stage.

Authors of the paper include Haiqin Zhou, Shunze Cao, Shuailong Zhang, Fenggang Li and Nan Ma. The work of this paper has been supported by the China Scholarship Council and Beijing Institute of Technology.

The paper, "Design of a fuel explosion-based chameleon-like soft robot aided by the comprehensive dynamic model," was published in the journal Cyborg and Bionic Systems on Jan 03, 2023, at DOI: https://doi.org/DOI:10.34133/cbsystems.0010

Reference

Authors: Haiqin Zhou1, Shunze Cao2, Shuailong Zhang3, Fenggang Li3, Nan Ma4*

Journal: Cyborg and Bionic Systems

DOI: 10.34133/cbsystems.0010

Affiliations:

1 Department of Mechanical Engineering, Beijing Institute of Technology, 100081, China

2 Department of Engineering Mechanics, Tsinghua University, Beijing, China. Shuailong Zhang and

3 School of Mechatronical Engineering and Beijing Advanced Innovation Center for Intelligent Robots and Systems, Beijing Institute of Technology Beijing 100081, China

4 Department of Engineering of Lancaster University, Lancaster, LA1 4YW, UK

A brief introduction about yourself.

About Dr. Nan Ma:

Dr Nan Ma is curently a Senior Teaching Associate with the School of Engineering, Lancaster University, Lancaster, U.K. His PhD degree was obtained from Beihang University in 2020, He worked in the University of Nottingham as the Research Fellow for the Innovate of UK supported project (CHIMEAR, Project Grant: £2,413,639), developing a long stiffening continuum robot (length: 1.5 m, diameter: 12.6 mm, expanded dimension of stiffening section: 120 mm from nature dimension of 13 mm) for the engine combustor inspection and maintenance (Roll-Royce, Trent 900). After that, he worked at the Lancaster University as the Research Associate for leading the EPSRC supported project (ASUNDER, Project Grant: £249,890), developing a dual-arm robotic system for the sample retrieval from the underwater nuclear environment (Japan, Fukushima Daiichi). He has more than 15 papers published in the area of advanced robotics up to now.

Personal Homepage: https://www.lancaster.ac.uk/sci-tech/about-us/people/nan-ma

END