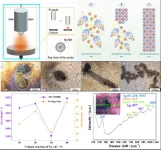

Barium strontium aluminum silicate (BaxSr1−xAl2Si2O8, BSAS) ceramics possess both phase stability and resistance to water vapor corrosion, making them ideal materials for radome technology and electronic packaging. To address the low tolerance of BSAS ceramics to damage and defects, the introduction of nano-reinforcements is an effective approach to enhance their strength and toughness. SiC nanowires (SiCnws) exhibit high strength and hardness inherited from SiC ceramics, along with the excellent toughness and elasticity characteristic of nanomaterials, making them ideal candidates for toughening BSAS ceramics. The reinforcing and toughening effects of nano-reinforcements are primarily related to their dispersion and interfacial bonding. Poor dispersion can result in the formation of closed pores during densification, while strong interfacial bonding can prevent effective crack deflection, thereby limiting the reinforcement and toughening effects of the nanomaterials. Finding a strategy to optimize the dispersion of SiCnws and achieve stable crack deflection is key to fully utilizing their reinforcing and toughening effects, and it is significant for enriching the theoretical framework of ceramic reinforcing and toughening mechanisms.

Recently, a team led by Xiaomeng Fan from Northwestern Polytechnical University, China reported a low-modulus brittle interface design method for reinforcing and toughening multiphase ceramics. By constructing an embedded SiO2 interface between SiCnws and BSAS, and through the tracking of microstructure and interface structure, they analyzed the reinforcing and toughening mechanisms, optimized the mechanical performance of BSAS ceramics. This work provides a new design approach for interface structure in multiphase ceramics, as well as for their reinforcing and toughening.

The team published their work in Journal of Advanced Ceramics on May 6, 2024.

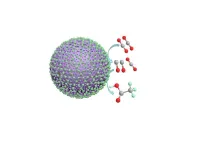

“In this report, highly dense SiCnws/SiO2/BSAS multiphase ceramics were prepared using hot-press sintering, with clear phase boundaries between the three phases. Utilizing STEM-HAADF technique, it was confirmed that the amorphous SiO2 is embedded in an irregular shape between the cubic SiCnws and monoclinic BSAS, forming an interface-like structure.” said Xiaomeng Fan, Associate Professor from Science and Technology on Thermostructural Composite Materials Laboratory at Northwestern Polytechnical University, an expert in materials science whose research interests on ultra-high temperature ceramic matrix composites.

“During the densification process, ceramic powders with good flowability are crucial for improving the dispersion of nano-reinforcements. According to the He and Hutchinson criterion, constructing a low modulus interface is key to inducing crack deflection. Therefore, we proposed an innovative hypothesis to optimize the reinforcing and toughening effect of nano-reinforcements by constructing a brittle interface: introducing an embedded SiO2 interface with low softening temperature and low modulus between SiCnws and the BSAS ceramic matrix,” said Xiaomeng Fan. “The results confirmed the hypothesis. First, molten SiO2 can cover ceramic particles under pressure, reducing contact stress during the sintering process and improving the flowability. Simultaneously, during sintering, molten SiO2 acts as an embedded interface between SiCnws and BSAS grains, weakening the interfacial bonding between them. This collectively optimizes the strengthening and toughening effects of SiCnws.”

This work optimizes the ceramic interface structure by adjusting the SiO2 content and systematically studies the reinforcing and toughening mechanism by predicting crack propagation behavior at the interface using the He and Hutchinson criterion. The optimized ceramics exhibit flexural strength and fracture toughness of 193±16 MPa and 3.1±0.5 MPa·m1/2, respectively, representing improvements of up to 52.6% and 94.0% compared to the non-optimized ceramics. “This work is significant for the commercial application of BSAS ceramics and provides new design strategies for the interface structure design to reinforce and toughen the multiphase ceramics,” said Xiaomeng Fan.

However, more detailed research is needed to explore the suitability of BSAS for commercial applications and the feasibility of applying this strategy to optimize the mechanical properties of other multiphase ceramics. In this context, Professor Fan has proposed three potential directions for future work: enhancing the thermal stability, water vapor corrosion resistance, and their coordination with mechanical performance; optimizing related preparation processes; and investigating the applicability of this strategy to other multiphase ceramic systems.

Other contributors include Xin Li, Haojie Luo, Jimei Xue, Fang Ye, Yongsheng Liu from Science and Technology on Thermostructural Composite Materials Laboratory at Northwestern Polytechnical University in Shaanxi, China; Xiaoke Lu from Frontier Institute of Science and Technology at Xi'an Jiaotong University in Shaanxi, China.

This work was supported by the National Key R&D Program of China (No. 2022YFC2204500), and the National Natural Science Foundation of China (No. 52231007).

About Authors

Dr. Xiaomeng Fan is an Associate Professor at the School of Materials Science and Engineering, Northwestern Polytechnical University. He received his Ph.D. in Materials Science from Northwestern Polytechnical University in 2015, and subsequently conducted postdoctoral research at the University of Erlangen-Nuremberg in Germany. In March 2017, he joined Northwestern Polytechnical University. His research focuses on high-temperature load-bearing and wave-absorbing integrated materials, as well as ceramic matrix composites with high thermal and mechanical stability. He aims to elucidate the relationships between microstructure, macroscopic mechanical/electromagnetic properties, and high-temperature environmental applications. To date, he has published over 120 peer-reviewed academic papers.

Dr. Xin Li is a postdoctoral researcher at City University of Hong Kong. He obtained his Ph.D. from the School of Materials Science and Engineering at Northwestern Polytechnical University in 2023. His research focuses on the design, fabrication, and characterization of functional ceramic materials. He primarily works on the electromagnetic functional design of materials, analysis of multi-spectral response mechanisms, and micro/nano-structure design. To date, he has published over 20 peer-reviewed academic papers.

About Journal of Advanced Ceramics

Journal of Advanced Ceramics (JAC) is an international academic journal that presents the state-of-the-art results of theoretical and experimental studies on the processing, structure, and properties of advanced ceramics and ceramic-based composites. JAC is Fully Open Access, monthly published by Tsinghua University Press, and exclusively available via SciOpen. JAC’s 2023 IF is 18.6, ranking in Top 1 (1/31, Q1) among all journals in “Materials Science, Ceramics” category, and its 2023 CiteScore is 21.0 (top 5%) in Scopus database. ResearchGate homepage: https://www.researchgate.net/journal/Journal-of-Advanced-Ceramics-2227-8508

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END