Their research is published in the journal Carbon Future on September 24, 2024.

Today, graphite is the most commonly used material for anodes in lithium-ion batteries. Graphite can operate at a low voltage, is readily available, and cost effective. While graphite materials have been used as the anode for lithium-ion batteries for almost 30 years, there is still room for greater development and application of graphite anodes.

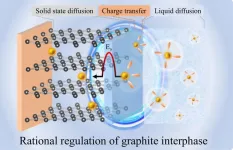

Graphite was not used in the earliest lithium-ion batteries because of its compatibility issue with the electrolyte used at that time. A little later, scientists discovered that ethylene carbonate could be used to form a protective layer, known as the solid electrolyte interphase, on the surface of graphite anodes. “The solid electrolyte interphase plays a multifaceted role by bolstering electrochemical stability, affecting the transport of ions at the interphase and the associated impedance, guiding the design of electrode materials, and acting as a diagnostic tool for battery health,” said Qiang Zhang, a professor at Tsinghua University. A well-structured solid electrolyte interphase layer is essential for graphite anodes to achieve high efficiency and stable performance. Although the components of the solid electrolyte interphase are a very small part of the battery, their impact on overall battery performance is significant.

To better understand the graphite interphase, the team undertook their review. “The pursuit of deeper insights into the properties of the solid electrolyte interphase and its dynamic behavior is essential for propelling battery technology forward, steering it towards safer, more efficient, and longer-lasting energy storage systems,” said Zhang. In their review, the research team noted six insights related to carbon anodes.

With the rise of new energy sources and the electrification of transportation and industry, the demand for graphite anodes continues to grow. The team notes the future potential for carbon-silicon composite anodes prepared from silanes for high energy density batteries and the optimization of carbon-lithium metal composite anode for solid state batteries.

The production of artificial graphite anodes is both costly and a highly energy-intensive process. The team notes the need for reducing carbon emissions and energy consumption in artificial graphite manufacturing through innovative graphitization technologies.

The team notes that it is crucial to establish data associations and data-driven models to collect performance characteristics of lithium-ion batteries in practical conditions. This will allow researchers to predict the battery life, gain an in-depth understanding of the characteristics of graphite electrodes in various dynamic processes, and optimize the factors for preparing lithium-ion battery cells, so that battery performance is improved.

Lithium plating in graphite electrodes is a technical challenge that critically affects safety performance. The team recommends monitoring the formation of dendrite and mitigating its side-impacts.

The team also recommends interface regulation for promoting the high-quality development of graphite. This requires a combination of basic theoretical research, in-situ or operando characterization techniques, and data-driven process development.

The recycling of electrode materials, especially graphite, from spent batteries is an important industry focus. The team recommends a comprehensive look at the energy consumption, emissions, costs, and material properties in the recycling process.

Even though graphite has been the anode material in lithium-ion batteries for almost three decades, the investigation into the interphase chemistry of graphite anodes continues to evolve. Graphite-based anode materials offer a wide range of applications in lithium-ion batteries. They also have potential applications in emerging energy storage technologies, such as potassium-ion batteries, dual-ion batteries, and calcium-ion batteries.

“Carbon materials have joined our life for thousands of years. This is an era full of opportunities because the demand and requirements of high-performance carbon materials are higher than ever; at the same time, it is also an era full of challenges as our understanding of the interface of carbon materials is still limited, and precise synthesis technology still has a long way to go. The current era urgently needs efficient preparation technologies with low or even negative carbon emissions to produce better carbon materials for building a better life,” said Zhang.

The research is funded by the National Key R&D Program of China, S&T Program of Hebei, National Natural Science Foundation of China, the Beijing Natural Science Foundation, the Seed Fund of Shanxi Research Institute for Clean Energy, the Tsinghua University Initiative Scientific Research Program, and Ordos Laboratory.

The research team includes Bin Cao from Tsinghua University and Xi’an University of Science and Technology; Mengjiao Du, Zirong Guo, and Huan Liu from Xi’an University of Science and Technology; Chong Yan and Jia-Qi Huang from Beijing Institute of Technology; Aibing Chen from Hebei University of Science and Technology; Xiang Chen from Tsinghua University and Sungkyunkwan University; Cheng Tang from Tsinghua University; and Qiang Zhang from Tsinghua University and Ordos Laboratory.

About Carbon Future

Carbon Future is an open access, peer-reviewed and international interdisciplinary journal, published by Tsinghua University Press and exclusively available via SciOpen. Carbon Future reports carbon-related materials and processes, including catalysis, energy conversion and storage, as well as low carbon emission process and engineering. Carbon Future will publish Research Articles, Reviews, Minireviews, Highlights, Perspectives, and News and Views from all aspects concerned with carbon. Carbon Future will publish articles that focus on, but not limited to, the following areas: carbon-related or -derived materials, carbon-related catalysis and fundamentals, low carbon-related energy conversion and storage, low carbon emission chemical processes.

About SciOpen

SciOpen is an open access resource of scientific and technical content published by Tsinghua University Press and its publishing partners. SciOpen provides end-to-end services across manuscript submission, peer review, content hosting, analytics, identity management, and expert advice to ensure each journal’s development. By digitalizing the publishing process, SciOpen widens the reach, deepens the impact, and accelerates the exchange of ideas.

END